CFS flats

The Future of Biometrics Is Here

Introducing CFS flats—the world’s first FBI-certified 3D contactless fingerprint scanner.

CFS flats represents the pinnacle of fingerprint scanning technology – a high-quality 3D contactless fingerprint scanner that’s changing how we think about biometric identification.

Powered by Bluelynes Technology®

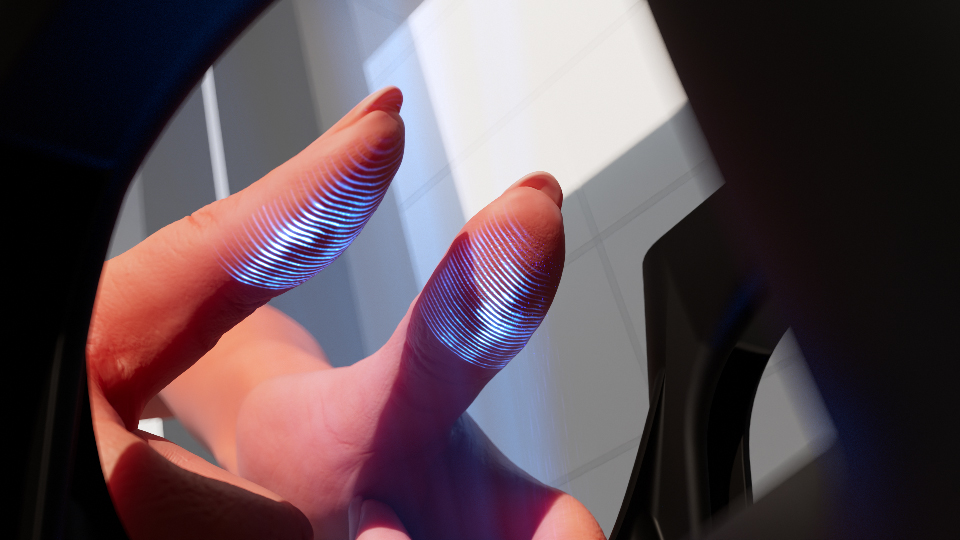

CFS flats uses structured blue light for 3D reconstruction. A known pattern is projected on and deformed by the surface structure of the finger. By imaging the deformed pattern with a camera, the 3D surface shape can be reconstructed via triangulation. An unwrapping algorithm transforms the 3D fingerprint scan to a 2D image, thereby providing important compatibility with today’s infrastructure of contact-based 2D fingerprint databases. Therefore, not only can CFS flats be used for verification, but also for enrolment in these 2D fingerprint databases.

The 3D contactless fingerprint scanner CFS flats does not just take a picture of the fingerprint, but instead takes a full 3D image of the fingerprint, creating a 3D point cloud of the surface of the fingers. CFS flats takes up to eight million data points per scan, 13 point-clouds per second, achieves a micron-scale depth resolution, and outputs data in the government standard fingerprint quality (e.g. 500ppi resolution).

CFS flats scanner successfully captures fingerprints in all conditions and functions optimally independent of ambient lighting, motion, skin color variation, and skin moisture levels. The CFS flats scanner simultaneously captures four flat fingerprints significantly faster than contact-based devices (where good contact with the scanning surface is required).

Resolution down to the micron scale

3D Image capture significantly faster

More than 5 million 3D points

Faster than with contact-based devices

SPEED

The speed and precision of capture makes CFS flats scanners the ideal solution for a wide range of applications, including airport and border control, access control systems and other public venues where the highest level of security is demanded.

The State of Fingerprint Biometrics Today

Traditional contact-based fingerprint scanners have been the standard for decades, but they come with significant limitations that impact reliability, hygiene, and user-experience.

1. Inconsistent Image Quality

Contact-based scanners rely on direct skin contact with a flat surface. Variations in finger pressure, moisture, dirt, or skin conditions (like dryness, cuts, or wear) often lead to incomplete or low-quality images—compromising the accuracy of biometric identification.

2. Hygiene Concerns

In high-traffic environments, contact sensors become hotspots for germs and bacteria. Shared surfaces raise concerns in settings like airports, hospitals, and government offices, where hygiene and public health are critical.

3. Wear and Tear

Repeated physical contact leads to gradual wear of the sensor surface, reducing performance over time. Maintenance costs and the need for regular calibration increase the total cost of ownership.

4. User Friction

Users must align their fingers precisely, often leading to delays or failed attempts—especially among individuals with worn fingerprints, manual laborers, or the elderly. This affects both speed and satisfaction.

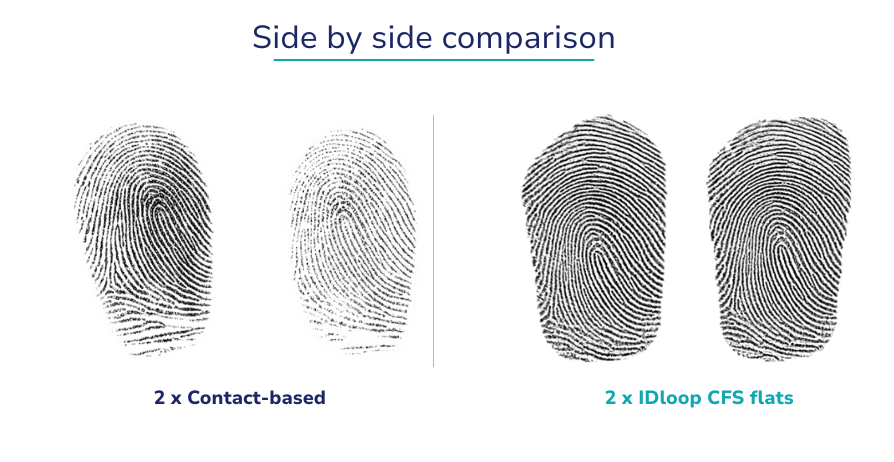

This side-by-side comparison highlights the inconsistent image quality of contact-based fingerprint scanners compared to the consistent, high-image quality images produced by CFS flats, our true 3D contactless fingerprint scanner.

The contactless advantage

Unlike traditional scanners that require physical contact, CFS flats captures perfect fingerprint scans without users ever touching a surface.

This contactless aspect protects the user from any bacteria, viruses and/or chemicals that might have been left on the surface of the device by previous users. In addition, no latent prints are left on the scanner from previous users, which can pose security problems due to false matching.

The contactless workflow also assists the operator from needing to clean the surface between uses, decreasing the cost of operating materials, and speeding up the time of acquisition.

Normal wear-and-tear and device damage also is drastically reduced simply because the device does not need to be touched. Common contact-based scanner challenges, such as scratched surfaces, become obsolete.

DOWNLOAD OUR WHITE PAPERS

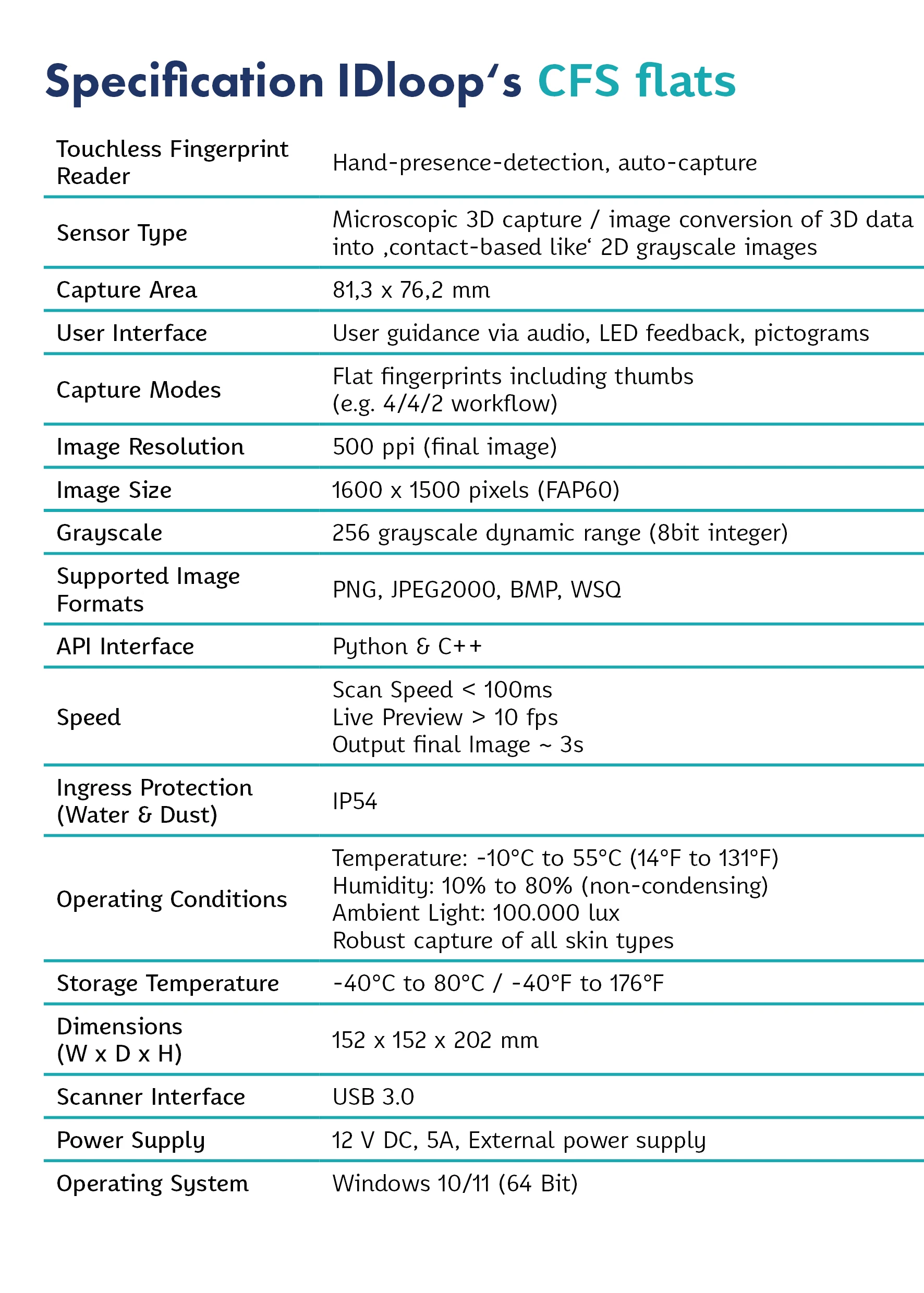

CFS flats Specifications

Download the CFS flats Data Sheet

Download the Introduction to CFS flats Whitepaper

Download the CFS flats vs Smartphone Whitepaper

IDloop GmbH

Moritz-von-Rohr-Straße 1a

07745 Jena | Germany

+49 (0)3641 55405 0

Co-funded by the Free State of Thuringia

As part of the consulting guidelines of the Free State of Thuringia, IDloop GmbH receives funding for consulting and process support. These support strategies for the development and sustainable positive development and safeguarding of SMEs. The resulting findings and recommendations for action are recorded in a consultancy report. Funding is provided by the European Social Fund Plus and the Free State of Thuringia.